Future Dye: A sustainable color revolution.

According to the World Bank, almost 20% of global water pollution is caused by the process of dyeing textiles. To future-proof and continuously improve our sustainability, we need to do our part. That's why Elvine started a sustainable dye revolution and chose the Solution Dye process instead of traditional dyeing methods. We call it Future Dye.

Less water, fewer chemicals.

Compared to traditional dyeing methods, the Solution Dye process offers:

• Uses up to 85-95% less water during the dyeing process

• 90% less chemical consumption

• Up to 30–40% less energy is consumed during the process

• CO2 emissions are reduced by 30%

So how does the solution dye process work?

In traditional methods, the dye is on the surface of the yarn. Solution Dye mixes the dye evenly throughout it. The process goes something like this:

1. Color pigments are mixed directly with a base of recycled raw polyester (we like to reuse our existing resources) or a base of new polyester.

2. The mixture is heated and the color is evenly distributed. Fabric fibers are then extruded and spun into yarn.

3. The yarn is woven into fabric.

4. Future-proof jackets are manufactured.

5. You stay warm and look great.

Colorfast, future-proof:

Because the dye is mixed into the fabric fibers, a consistent color can be achieved - season after season, batch after batch. It also won't fade or discolor like traditional dyeing methods and can withstand harsh city climates, washing machines and detergents. Future-proof dyeing. That's part of how we design future-proof clothing. High-quality and timeless designs that will stay with you season after season.

Technical features of Future Dye / Solution Dye:

Compared to conventional processes, the solution dye process uses up to 85% less water (up to 95% for dyeing in general):

• Fewer chemicals up to -67%

• Less energy -39%

• Low CO2 emissions -60%

• Brilliant color fastness.

Mech Stretch:

Our Light Stretch is dyed using a solution dye process that uses less water, fewer chemicals, less energy and fewer CO2 emissions. It is made from recycled polyester and has been bonded to a wind and waterproof recycled membrane, giving it a water column of 10,000 mm. The surface has been treated with Bionic Finish® Eco, an environmentally friendly water-repellent impregnation.

Feel: Soft, stretchy and deeply matt.

Composition: 100% recycled polyester

Construction: Smooth

Impregnation: Rudolf Eco Bionic

Water column: 10,000 mm (recycled

Membrane)

Breathability: 10,000 mvp

Dyeing technique: Solution Dye

Outer fabric, membrane, lining, zippers:

Everything recycled.

Bionic Finish® ECO:

The fluorine-free water-repellent impregnation. When we at ELVINE treat our garments with a water-repellent treatment, we always use Bionic-Finish® Eco. Bionic-Finish® Eco from the Rudolf Group is a unique, patented water-repellent, oil-repellent and dirt-repellent finish for textiles that does not use harmful fluorine compounds.

THERMORE® Ecodown® fibers:

Light, soft, fluffy, warm: Ecodown® fibers are the soul of your jacket. Ecodown® fibers set a new standard in their category and are designed to offer superior fluffiness, warmth and recovery thanks to the unique multi-shape structure.

And of course, they are free from animal ingredients and also made from 100% recycled fibers. Durability is ELVINE's top priority and Ecodown® fibers are the only fiber-free product that doesn't clump or create cold spots after washing. And unlike most competitors, Ecodown® fibers are also kind to the environment by not using microfibers, which ultimately pollute our lakes and seas and potentially contaminate our food.

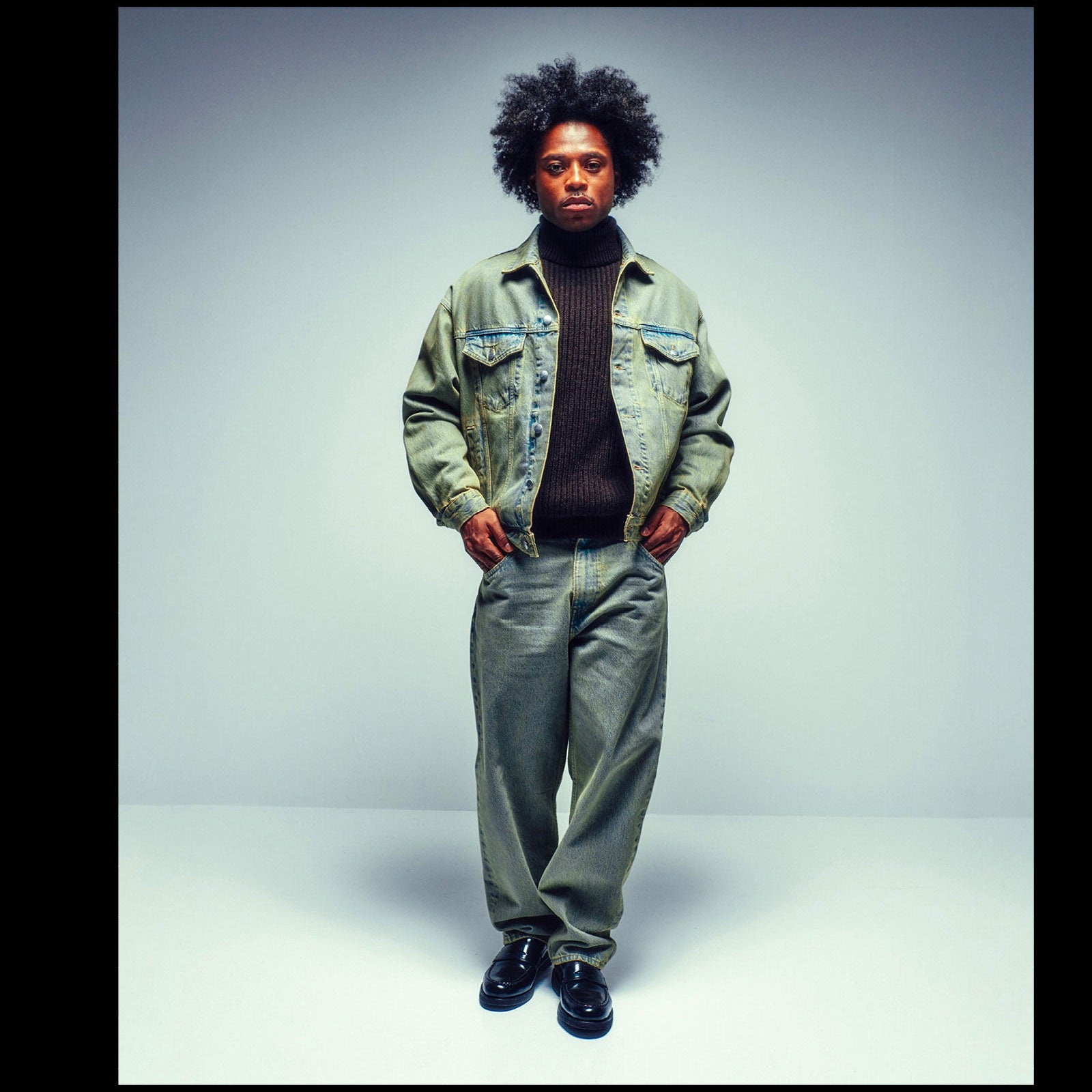

August Black

winter jacket

Waterproof fabric: 10,000 mm water column

Quality : Mech Stretch

Laine Moss

jacket for deep winter

Waterproof fabric: 10 000 mm water column

Quality : Mech Stretch

jacket for deep winter

Waterproof fabric: 10 000 mm water column

Quality : Mech Stretch